CISDI’s core equipment is commended at home and abroad

Date:2024/7/31 Source: CISDI

“Your breakdown mill is technology intensive. The tight manufacturing schedule we required was challenging. But your tight-knit team overcame the difficulties and turned a negative into a positive, taking responsive, effective action to ensure all our requirements were met. CISDI fulfilled its promise and delivered the equipment on-schedule and to quality. It is greatly appreciated.”

This letter of thanks came from Sichuan Province-based Changcheng Special Steel, which operates under Pangang Group.

It commended CISDI’s role in the supply of Changcheng’s 2-roll reversing breakdown mill and its stable performance.

Changcheng Special Steel’s products rank as China’s largest specifications for special steels bar and flat blooming.

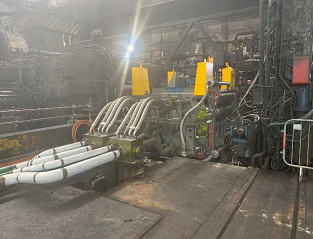

The operational BDCD mill at Pangang Changcheng Special Steel

The BDCD mill is a star product created by CISDI Equipment Co, which is sited in the Jiangjin District of Chongqing.

CISDI HQ’s manufacturing base has long been committed to enhancing product and service standards by focussing on innovation and total process quality control and its brand image is steadily rising, both in China and beyond.

A concept of product commercialisation has been implemented with strong focus and direction.

Adhering to the principle of creating standardised, seriation, modular and refined products, CISDI Equipment has built a diversified, in-depth product design standard drawing bank.

Every product’s top-level design has been quality-assured, right from its research and development and technological process stages.

A deep integration of equipment design with manufacturing has been vigorously advanced. CISDI Equipment’s workshops carry out flexible manufacturing with specially-designated assembly lines, full-process visualised control and tailor-made quality planning and tracking throughout.

NHCD short-stress path rolling mill

NHCD mills achieve product precision to 1/3 to 1/4 DIN standard values and over 500 are sold each year.

China’s Baosteel and WISCO, Malaysia’s ASSB and around 100 other steel plants have successfully applied NHCD mills to their long products rolling lines.

NHCD mills play a critical role in smoothing dual high-speed bar rolling production at Desheng Steel Yunnan

A screenshot for online measurements of NHCD mills at Pangang Changcheng’s special steel bar rolling line

UMCD mills

CISDI’s universal mill UMCD is a breakthrough product manufactured by CISDI Equipment. It is classed as on a par with mills which China’s steel companies previously had to import.

Yongyang Special Steel took the lead with UMCD mills and applied them at its optimal light rail and heavy rail rolling lines, becoming China’s first rail production to operate with a Technology Control System.

Since their start-up in 2020 and 2021, equipment has been running safely and reliably at both lines, product dimensions have been stable and 91 per cent-plus mill availability coefficient.

The Hebei Province’s rail producer awarded a banner to CISDI Equipment after a year of hot commissioning, commending CISDI’s brand, product and service.

FSB creating huge values for TATA UK

CISDI’s FSB came in for glowing praise from Port Talbot Works under TATA UK in an equipment operation appraisal report.

It stated: “The finishing mill scale breaker has brought remarkable benefits to TATA UK’s hot rolling line. The CISDI supply features a modular design which reduces much of the major repair time. The new FSB can help us change to a spare unit within 36 hours, which was generally taking 8 to 12 days. It’s really creating huge values for us.”

The FSB was supplied to Port Talbot Works in 2019, marking an encouraging export of innovative design and core equipment to the developed economy.

The modular FSB in operation at Port Talbot Works, UK