CISDIFlex UHP DC EAF’s flexible power supply wins high praise

Date:2024/7/31 Source: CISDI

CISDI has channeled its power electronics research and development strengths into creating a game-changing flexible power supply unit.

The CISDIFlex is dedicated to an ultra-high-power DC electric arc furnace which is at the core of a Mini-mill and is charged with scraps for melting.

The Mini-mill is now a greener development trend in the global steel sector. Its energy consumption and carbon emissions are two thirds less than integrated mills with blast furnaces and basic oxygen furnaces at their core.

Scrap is a renewable energy source which can be recycled infinitely. To produce one tonne of billet from scrap can reduce 1.6 tonnes of carbon dioxide emissions and three tonnes of solid waste emissions.

CISDIFlex applies the latest insulate-gate bipolar transistor components and features pure-water cooling, modular design and fully-digital control.

It enables flexible, continuous regulation of current and voltage and solves problems such as large grid impact, inferior regulation of output voltage and current and the risk of poor impact resistance posed by the conventional thyristor DC power supply.

Nine patents have been applied for and CISDIFlex is already the winner of China’s Innovation Methods Contest.

Projects where CISDIFlex has been applied are demonstrating smart control against slip’s short-circuiting and arcing restarts.

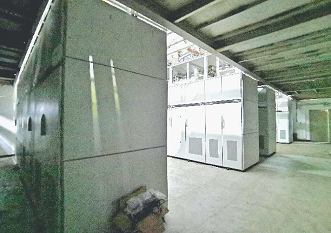

The patent-pending CISDIFlex

CISDIFlex at Pangang Changcheng Special Steel, Sichuan

December 2021 saw CISDI-SuperARC EAF’s hot commissioning at Pangang Changcheng Special Steel in China’s Sichuan Province. Power is supplied to the SuperARC by CISDIFlex and the result is stable liquid steel tapping throughout the entire melting process.

World-class technical indicators have been achieved:

Power output’s response speed: 0.1 millisecond;

Grid-side power factor: > 0.95;

Voltage and current fluctuation: < 3%;

Power supply’s overall loss: within 3%;

Power consumption saved: 10%.

The CISDIFlex working at Changcheng’s SuperARC

Tapping in process at Changcheng’s SuperARC

CISDIFlex at Yuxi Xianfu Steel, Yunnan

The world’s first CISDI-SuperARC EAF went operational at Yuxi Xianfu Steel in China’s Yunnan Province in August 2023.

The vessel’s capacity for alloy steel melting is 52 tonnes.

Xianfu’s CISDIFlex ranks as the largest in China for a single furnace, indicating a rated power of 58MW and a rated working current of 116kA.

Yuxi Xianfu Steel is rightly proud of its SuperARC, which is achieving world-leading performance indicators, product standards and operational reliability.

The CISDIFlex serving Xianfu’s SuperARC

CISDI’s expert team was onsite for CISDIFlex’s assembly and testing

Tapping in process at Xianfu’s SuperARC