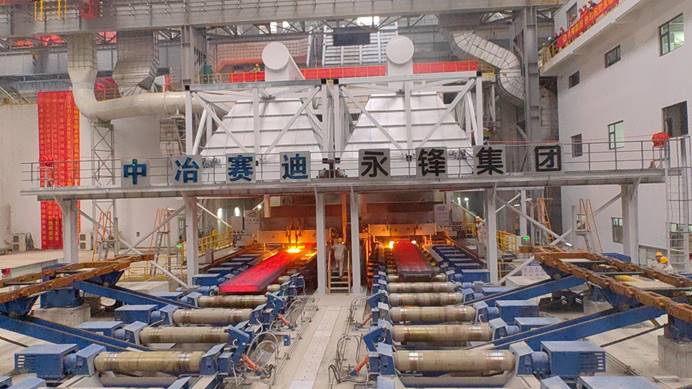

CCM3 is up and running at Yongfeng Steel Lingang phase II

Date:2024/5/21 Source: CISDI

Yongfeng Steel’s Lingang plant has now hot tested its continuous casting machine 3, an integral part of its phase II construction.

CISDI was contracted to supply and install two sets of the slab casters, each featuring two strands and with a specification of 2,150mm.

Both casters needed to be constructed at the same time, but as joint commissioning couldn’t be accommodated, CCM4’s construction and commissioning is due to be completed in June this year.

CISDI has supplied all process models, core tech and equipment. Its specialist products play a critical role in achieving higher quality, efficiency and smart manufacturing standards and lower-cost operation:

• mould’s online width adjustment

• mould’s hydraulic oscillation

• mould’s expert system

• high-precision segments

• mould’s electro-magnetic stirring

• strand’s electro-magnetic stirring

• 3D dynamic secondary cooling model

• dynamic soft reduction model

• hydrogen-oxygen torch cutter

• robot marking.

The CCM will stably produce quality carbon structural steel, high-strength structural steel and non-oriented silicon steel products.

The CCM3, now operational at Yongfeng Steel Lingang’s phase II in China’s Shandong Province

The CISDI team celebrates the CCM3 hot testing at Yongfeng Steel Lingang