CISDI’s new BOF thermal system modernises Lianfeng Steel

Date:2024/5/21 Source: CISDI

—— Spherical accumulator generates high quality steams with reduced costs

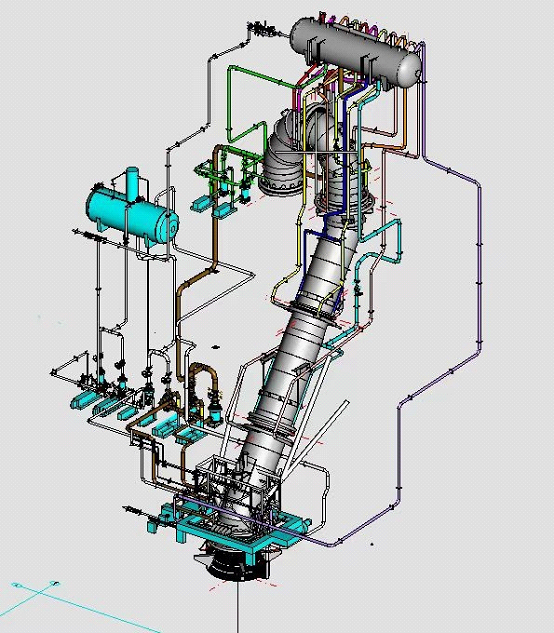

CISDI Thermal & Environmental Engineering Co has designed and supplied an innovative thermal system for a basic oxygen furnace at Lianfeng Steel’s New Meltshop 1 in China.

Now operational, the thermal system is applying an evaporative cooling system for the 160-tonne BOF and a spherical accumulator with a 400 cubic-metre volume.

In addition to generating high-quality steams, the simply-structured accumulator is reducing costs and maintenance and space requirements.

CISDI Thermal’s proprietary energy conservation and emission reduction expertise and its digital tech have modernised technological processes and productivity at Jiangsu Province-based Lianfeng Steel.

The BOF’s new evaporative cooling system was built after a modification of complicated existing pipework and the intertwined furnace building.

CISDI’s three-dimensional, collaborative design methods enabled cross-checking and removed duplication among engineering majors, which markedly improved the project’s efficiency.

The spherical accumulator was invented with a ring tower structure, which makes steams much drier.

Achievements include carbon neutral energy storage, a balanced regulation of gas source, supply and pressure, and a continuous supply of stable steams to users.

A 3D image of the CISDI-designed thermal system for Lianfeng Steel’s 160t BOF

Lianfeng Steel’s BOF thermal system is now in operation