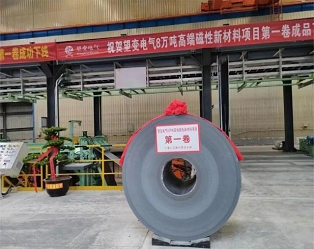

First chilled coil rolls out of Chongqing Wangbian Electric’s mill

Date:2023/9/19 Source: CISDI

The first chilled coil has successfully discharged from Chongqing Wangbian Electric Group’s new, hi-tech Sendzimir 20-hi reversing cold rolling mill.

The mill will produce up to 80,000 tonnes of orient high B (HiB) a year.

The entire production line comprises of a ZR mill, a continuous annealing decarburization and MgO coating line, a bell-type furnace, a continuous tension leveling unit and a welding preheating unit.

With the exception of the furnace, CISDI supplied all units - a new achievement for the company.

As the core material for manufacturing transformers, HiB directly affects the transformer’s energy consumption and energy efficiency levels.

HiB quality ranks as a major evaluation standard for a state’s high-value-added steel manufacturing technology.

CISDI’s mill has solved the problems of large resistance deformation and brittleness in rolling pieces, and enables accurate control of the challenging strip profile and thickness.

Standout features:

² To improve rigidity, the mill housing has been cast as one piece and is crown-less. Its pass features a heavy screw-down ratio.

² High production precision is achieved by hydraulic automatic gauge control and backer backup-roll’s eccentric screw-down gauge control.

² Advanced measurement, regulation and control systems ensure accurate profiling of intermediate and final products.

² Precision instrumentation, a powerful emulsion system and pressure-equalising sprayers precisely control rolling temperatures and meet requirements at various passes.

² Innovative de-oiling, strip edge purging and intensified fume exhaust expertise keep strip surfaces clean despite the large spray of emulsions.

² A multi-functional roll-changing unit adapts to all rolls and enhances HiB production.

² The mill has strong market prospects, as it is suitable for a wide range of applications - from producing oriented and high-grade non-oriented steels to stainless steel, high-tensile alloy steel and super-thin steel strips.

The first chilled coil produced by the CISDI-supplied 20-hi Sendzimir Mill