Breakdown Mills pass critical ex-works inspection

Date:2021/8/23 Source: CISDI

Representatives from China’s Xingcheng Special Steel and Hebei Yongyang Special Steel attended the ex-works inspections for their new breakdown mills.

The inspections were carried out at CISDI Equipment Co. in Chongqing’s Jiangjin District under joint witness of both customer and manufacturer, according to contractual terms.

The customers agreed they were satisfied with the mills.

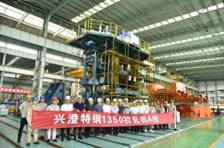

Xingcheng Special Steel’s Breakdown Mill

Along with CISDI’s team, Xingcheng Special Steel’s representatives took part in the tests at the general assembly shop of CISDI Equipment Co.

They inspected the checklist points ? mill’s top and bottom bearing chock locking devices, balancing devices, screwdown clutches and the mill roll change unit. Certificates of the materials and equipment documentation were also inspected.

The breakdown mill, in a diameter of 1,350mm, is a core part of CISDI’s services for upgrading mechanical, electrical and hydraulic systems for equipment from approaching roller table to runout roller table.

These upgrades will enable Xingcheng to produce large cross sections of work pieces - ranging from 700mm x 530mm squares and Φ700mm and Φ800mm rounds.

These rebuilds are critical to the improvement of the entire rolling line.

The expanded work pieces will play a strong role in boosting the competitiveness of the line’s final heavy bar product and its downstream processing lines.

The new mill will be delivered to the rolling plant in China’s Jiangsu Province. CISDI put forethought into the design and manufacture to ensure it will match with existing equipment and installation and commissioning will run smoothly.

The Breakdown Mill passes critical inspection at CISDI’s shop

Yongyang Special Steel’s Breakdown Mill

The mill, in a diameter of 1,350mm, was put through its roll pushing, lifting and locking movements. The tests resulted in all parameters meeting customer requirements.

CISDI has been contracted to supply the integrated mechanical, electrical and hydraulic equipment for Yongyang’s rolling lines - patented BDCD, UMCD and horizontal gantry-type and vertical straightening mills - involving the blooming, universal rolling, straightening, rail and section finishing lines.

The CISDI-supplied breakdown mill for Yongyang Special Steel’s quality rail and beam rolling line

CISDI has developed its own range of standardised breakdown mill products (BDCDs) in 21 specifications.

Since its first BDCD supply to Xingtai Steel in China’s Hebei Province in 2007, the company has made continuous improvements to its standardised rolling mill design, calculations, software development, manufacturing and after-care service.

Mills supplied to special steels and sections manufacturers in China are playing a part in the country’s intelligent, green, low-carbon and more efficient metallurgical developments.