Cleaner water at Chongqing Steel - with CISDI onboard

Date:2021/4/25 Source: CISDI

CISDI has been entrusted to revamp a central waste-water treatment plant at Chongqing Steel.

CISDI will be working to an EPC mode. Zero liquid discharge goals have been set and the project will be divided into three stages.

The first phase will solve urgent issues hampering production.

The steel plant’s current water supply and drainage system has failed to meet normal production requirements.

Problems include an inadequate supply of primary demineralised water, undesirable sludge treatment results, underperformance of waste-water recovery and an inability to meet zero liquid discharge standards.

CISDI’s front-end consulting recommendations, approved by Chongqing Steel, include expanding the existing deep processing system B, refurbishing the existing sludge treatment system and building a new brine treatment system C. A new concentrate pipeline network will be created.

In addition to solving immediate issues with production needs, Stage 1 solutions will successfully meet zero liquid discharge requirements in the project’s future stages, laying a solid foundation for turning Chongqing Steel greener, cleaner and more sustainable.

Link:

In response to the growing need for green steel transformation, CISDI has appointed a specialist team to research and develop zero liquid discharge technology and equipment.

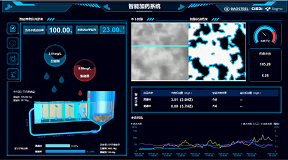

Its alum image identification and intelligent dosing system is achieving outstanding results at Baosteel Zhanjiang and Zenith Nantong Steel.

Zhanjiang Steel’s central water treatment plant has seen a 100 per cent compliance rate for water quality and a 30 per cent reduction in dosing quantities. The intelligent system has reduced the need for workers to carry out inspections of the water plant.

A screenshot of CISDI’s alum image identification and intelligent dosing system for a central water treatment plant