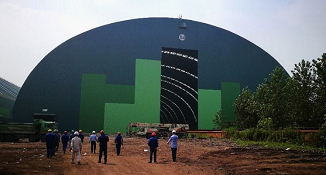

CISDI turns Baosteel Shanghai’s ore yard green

Date:2020/10/16 Source: CISDI

Baosteel Shanghai’s ore yard is now greener, cleaner and more economical.

CISDI’s standardised model B covered stockyard is now in place, a successful upgrade of Baosteel’s eco-friendly, closed stockyard system.

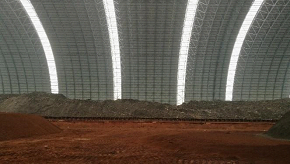

Originally open to the elements, stockpiles OL and OM have been enclosed with a vast roof formed from arched grids. A total floor area of 76,000 square metres has been covered. The arched grids form a span of 116 metres and a length of 600 metres.

The enclosed stockyard is expected to reduce material losses caused by wind and rain by 17,700 tonnes a year and save about $3.40 million per annum.

The plant’s environmental surroundings will also be improved and stock material handling costs will reduce.

The upgrade is part of Phase III of Baosteel Shanghai’s stockyard rebuild, the largest of its kind in global steel.

CISDI is providing tailored solutions for the rebuild, including patented intelligent, efficient and green storage, online upgrade and clean production technologies.

After the rebuild, nearly 800,000 square metres of the stockyard will be enclosed, encasing all raw materials and fuels.

The scheme will save 280,000 square metres of land and only a tiny amount of released dusts will enter the atmosphere - 95 per cent less than that previously released when the yards were open-air. Over 85 per cent of material losses will be avoided.

No onsite operators will be required for the stacking, reclaiming and transport operations at the closed stockyards.

The exterior of CISDI’s standardised model B stockyard at Baosteel Shanghai

Daylighting belts have been incorporated into the model B stockyard roof

Interior view of the model B stockyard at Baosteel Shanghai