CISDI’s stockyard rebuild has test run at Baowu Group Qingshan

Date:2020/3/27 Source: CISDI

Baowu Group’s

Qingshan Steel plant has put its rebuilt stockyard through a trial production,

by charging the raw materials into the ironmaking plant.

CISDI’s

eco-friendly and intelligent ECIA model C stockyard has been applied and

stockpile’s

maximum cross section has been expanded to 1,000 square

metres without changing the yard’s 90-metre span or its height.

Maximising

stockpile improves both the yard’s storage capacity and cost savings per tonne

of ores.

The top

eco-friendly stacker uses long-distance drag chains for its power, water and

gas supplies and for its communications.

Innovative use

of an air cable supplies compressed air to the stacker. This solves numerous

problems encountered by having an air compressor onboard the stacker, such as a

high fault rate, unstable operations and high operational cost. It also enables

the air-mist dust suppression device to run more stably and efficiently.

The stacking

belt conveyor is optimised for its remainder recovery technology and reduced

the cost.

Qingshan

Steel’s stockyard rebuild applies CISDI-patented autonomous process selection,

digital stockyard and unmanned stacker-reclaimer expertise.

It will enable

intelligent operations management and the Pocket Factory for the

foreseeable future.

An intelligent

centralised stockyard control centre is now on the agenda, which will

co-ordinate with WISCO’s intelligent centralised control centre for ironmaking

and upstream procedures.

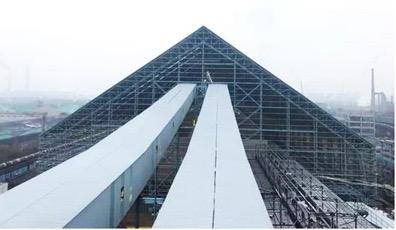

Raw materials being transported via belt conveyors into the ECIA C stockyard at Baowu Group’s Qingshan Steel