Aarti’s new rolling line will produce 200,000 tonnes of alloy bar a year

Date:2019/12/17 Source: CISDI

Aarti’s new rolling line will produce 200,000 tonnes of alloy bar a year

—— CISDI’s successful export to India starts on schedule

A new alloy bar rolling line at India’s Aarti Steels has started up on

schedule.

CISDI package supplied the IPR-based walking-beam reheating furnace,

breakdown mill and short-stress path rolling mill train. It has also provided

technical assistance and project management services.

The rolling line will produce 200,000 tonnes a year and the reheating

furnace’s hourly capacity is 40 tonnes.

Most of the final products will be round bar, flat bar, square bar and

hexagonal bar. The breakdown mill will bloom eight cross-section dimensions and

its final products will be in as many as 120 specifications.

The reheating furnace, which went operational two and half months early,

is an outstanding showcase of CISDI’s engineering originality and adaptation

skills.

Key Features:

● A

tailor-made energy saver, the furnace has been developed with a dual-combustion

system which relies on diesel and heavy oil. The fuel oil main and

upstream-burner oil return branch have been combined to ensure oil pressure

stability at the inlet of the burner.

● The steam system with heat tracing and the

automatic water drainage system facilitate a certain viscosity in the flow of

oil, which ensures its combustion.

● Burner oil can be atomised, thus creating a

stable flame and achieving higher efficiency.

CISDI counteracted numerous challenges during construction by stationing

a project team and its engineers on-site to give guidance and supervision

throughout the project cycle.

The CISDI-supplied breakdown mill in operation at Aarti Steels

Aarti’s reheating furnace discharges a billet for the rolling line supplied by CISDI

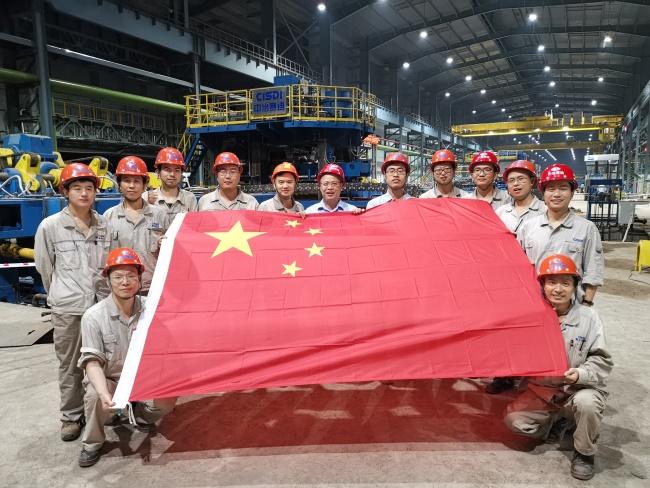

CISDI’s project team is pictured at the alloy bar rolling line on Chinese National Day, October 1st