Baowu Group Bayi Steel’s intelligent hot-rolled coil warehouse

Date:2019/10/18 Source: CISDI

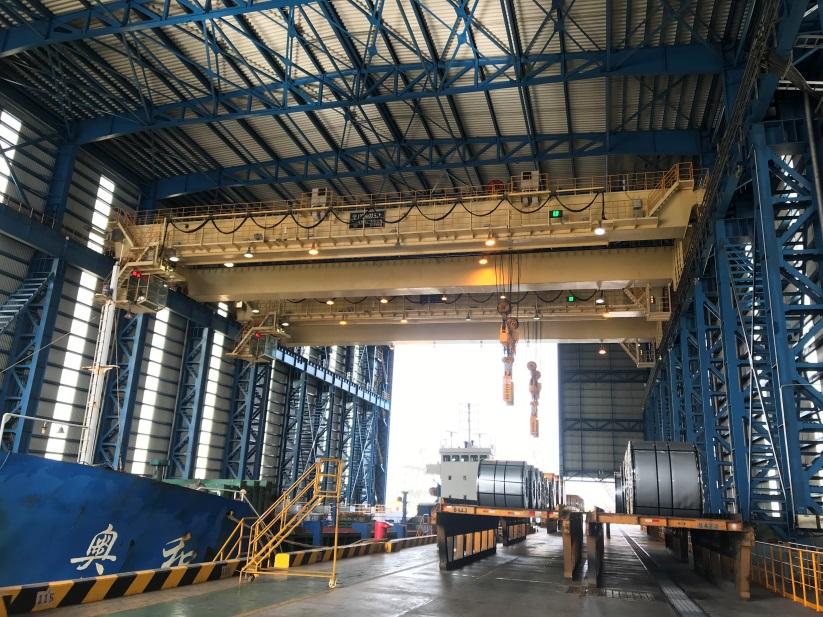

Baowu Group Bayi Steel’s intelligent hot-rolled coil warehouse

—— Achieving intelligent warehousing for steel

Bayi Steel’s hot mill now boasts China’s first intelligent, unmanned

warehouse to the standard set by Industry 4.0.

Operational since May, the warehouse is capable of autonomous driving,

smart warehousing and machine vision.

As a result, processes including truck outbound, walking beam

offloading, warehouse pile switchover and transfer car reloading can operate

without the need for workers.

The seven ‘smart’ cranes at the warehouse are also unmanned and across

the warehouse, the number of manual operators required has been reduced by at

least 50 per cent. The highest reduction in manpower requirements has been made

in high-heat and hazardous posts.

Outbound efficiency can be improved by 50 per cent; the maximum lifting

capacity has been increased by more than 10 per cent and in addition, the risk

of damaging coil which can occur during lifting or transportation is greatly

reduced.

CISDI’s intelligent warehousing expertise can also be seen at Zhanjiang

Steel’s all-weather wharf, a rebuild and transformation project which has

greatly reduced manpower requirements.

Conventional wharfs rely heavily on manual operators for machine

scheduling and lifting and loading coil product onto ships. Working conditions

are usually poor and fraught with safety hazards.

CISDI’s intelligent solutions to these problems - the driver-less crane,

warehousing intelligent control and machine vision - enable the entire wharf to

operate with 50 per cent fewer staff.

Online operation takes total control of machinery at the port and

enables machinery inside the ship’s cabin to run with reduced labour.

The intelligent

control desk at Bayi Steel’s hot-rolled coil warehouse

The intelligent

hot mill coil warehouse at Bayi Steel now has unmanned operations, which makes

it safer and more efficient

Zhanjiang Steel’s all-weather wharf is now working intelligently and autonomously